Business Process Improvement: Steps & Methodologies

ProjectManager.com

OCTOBER 14, 2024

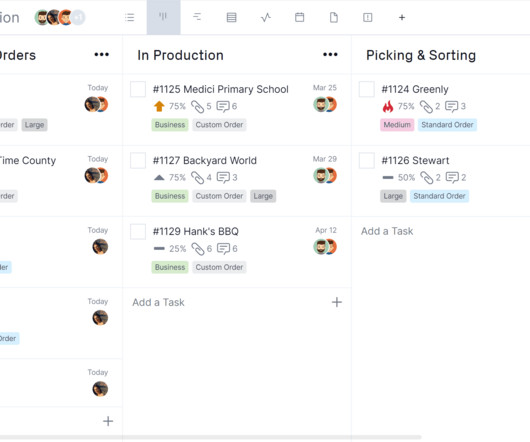

Operational: This includes the core business and creates a value stream, such as orders from customers, opening accounts, manufacturing, etc. Supporting: This includes those processes that support other processes such as accounting, recruitment, technical support, etc. Try it yourself with this free 30-day trial.

Let's personalize your content